Allspark Solutions provides ongoing electrical maintenance for industrial facilities, including food manufacturing, processing plants, and packaging operations. Our maintenance work is structured to support reliable production and reduce unexpected equipment failures by identifying electrical issues early and addressing them before they affect output.

Industrial Electrical Maintenance

Preventative Maintenance for Industrial Equipment

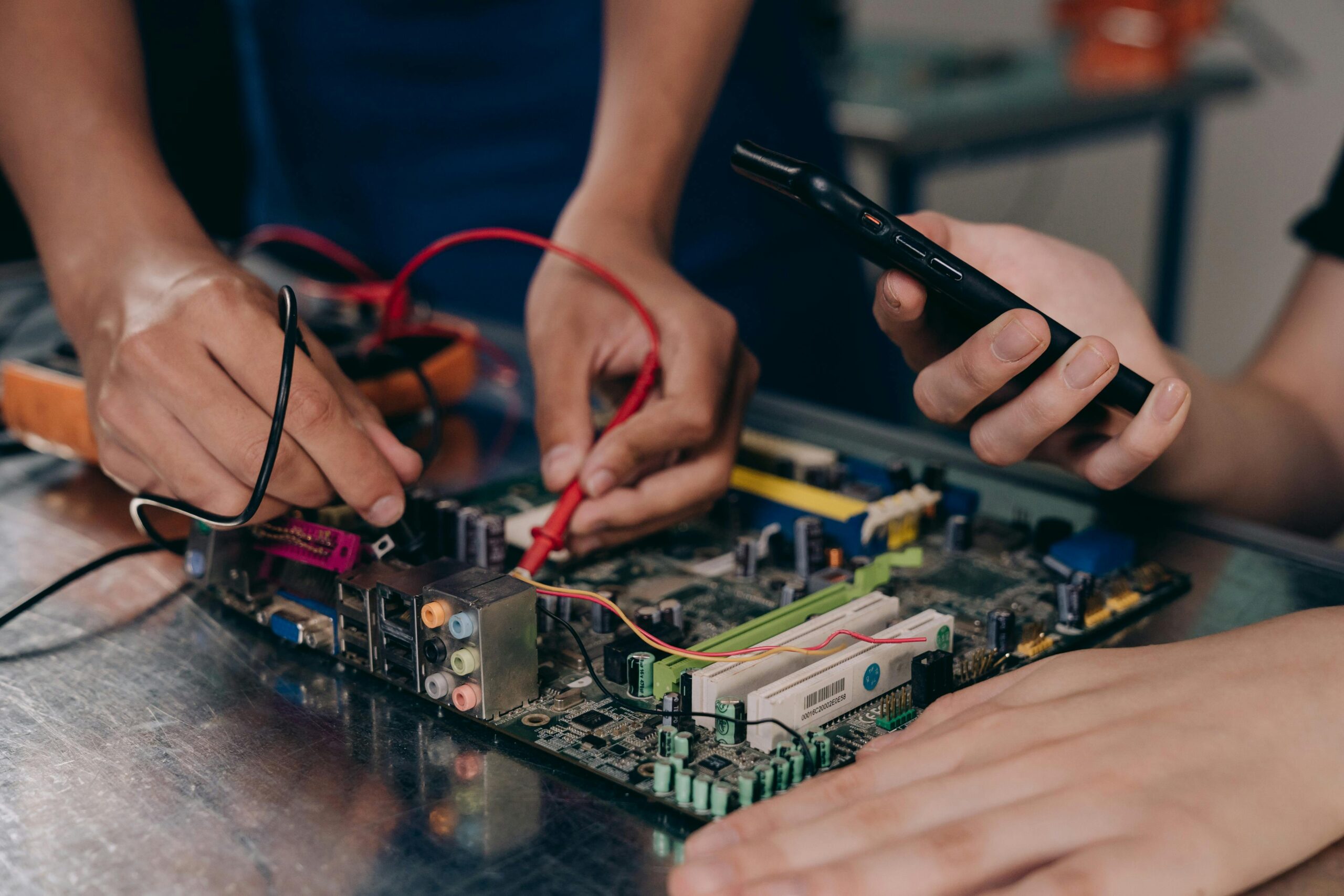

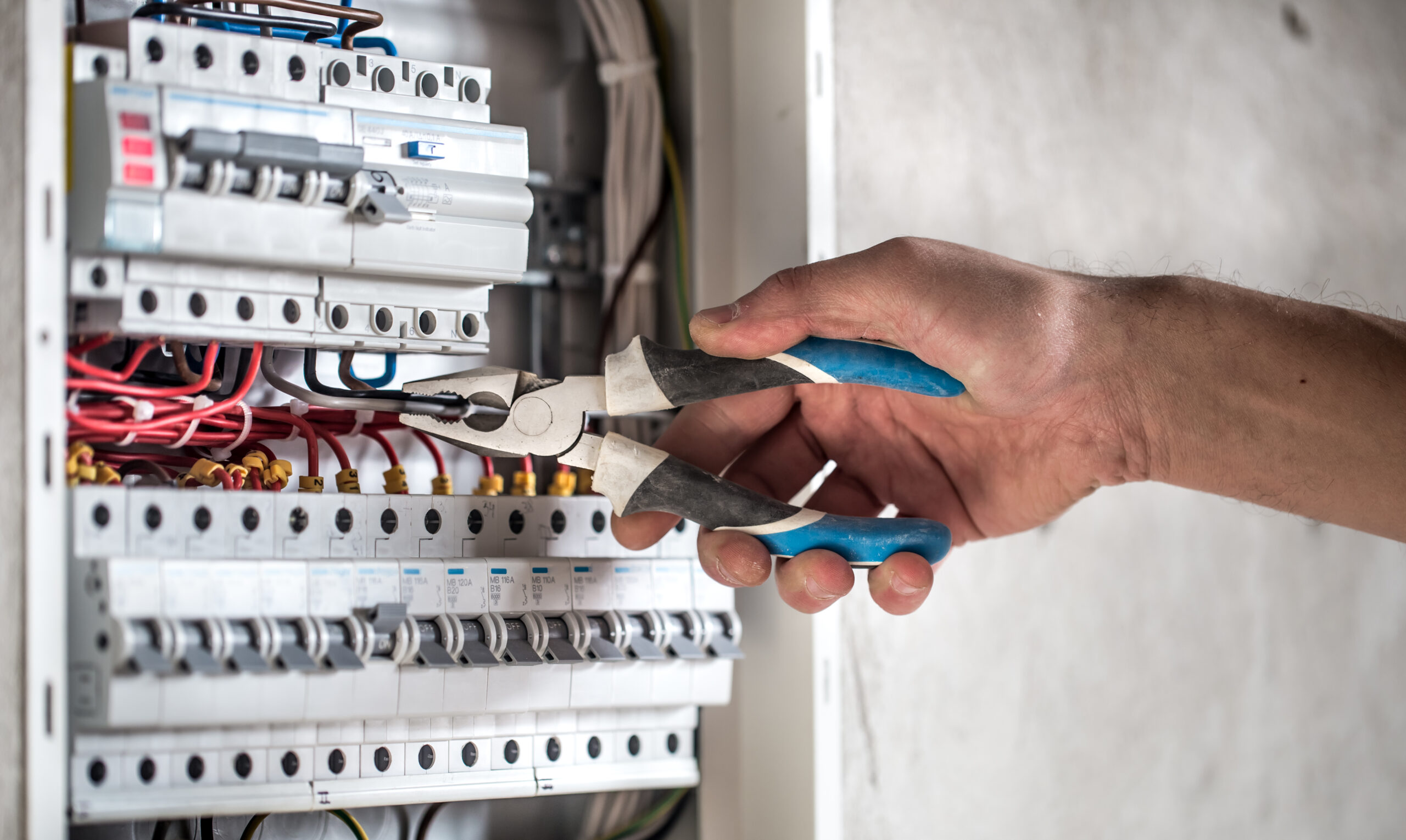

We assist with scheduled inspections, servicing of machinery, condition checks on motors and drives, and general electrical reviews designed to keep equipment operating consistently. Our experience working with automated and semi-automated systems enables us to identify developing faults in sensors, wiring, control devices, and electrical components. This approach helps facilities maintain predictable production schedules and manage their equipment more effectively over the long term.

Flexible Ongoing Maintenance Support

Maintenance services can be arranged as once-off checks, ongoing weekly or monthly programs, or integrated into shift coverage as required by the facility. All work is documented, allowing clients to maintain clear records of equipment condition and any repairs that may be required in future. By implementing consistent maintenance, businesses benefit from fewer disruptions and safer operating conditions across their production environment.

Arrange a Maintenance Program

For routine maintenance, shift coverage, or scheduled electrical inspections, contact Allspark Solutions to organise a tailored maintenance plan.

Sydney

Flexible based on project and site requirements